HBSE/NBSE upgrade proposal

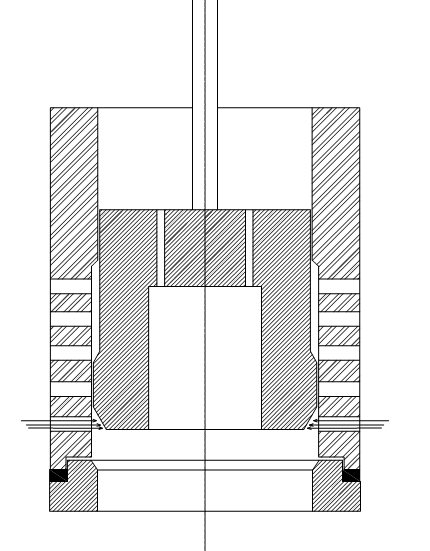

The high pressure bypass valve of the HBSE/NBSE turbine is a common valve structure in the 40% startup bypass of the coal fire power unit.Its characteristics are:

1) The balanced valve core structure design requires less execution force.

2) Simple structure and low failure rate.

However, from the point of view of the use, the main problem of this type of valve is that the water erosion resistance is weak, and the leakage of the sealing surface caused by water erosion often occurs. The sealing form of this type of valve determines that this type of valve can only pass. Strengthen the water erosion resistance at the sealing surface to slow the damage of the sealing surface. The specific method is to weld the water-resistant alloy (Stellite alloy, etc.) on the sealing surface. However, from the long-term experience, the effect is not satisfactory. There is still a large amount of water erosion causing the valve to leak. As a result, the power plant loses a large amount of high-energy steam, which leads to a decrease in power generation efficiency and an increase in unit energy consumption.

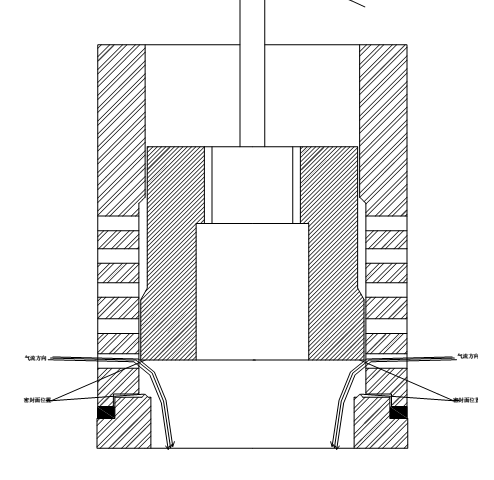

Therefore, it is necessary to make corresponding modifications to this type of valve. On the basis of retaining the advantages of this type of valve, it is a trend to carry out targeted transformation against the situation of insufficient water erosion capability. From the point of view of some units that have been modified, Good results have been achieved. There are still no water erosion leaks in the cold start of the modified unit.

The specific transformation plan is as follows:

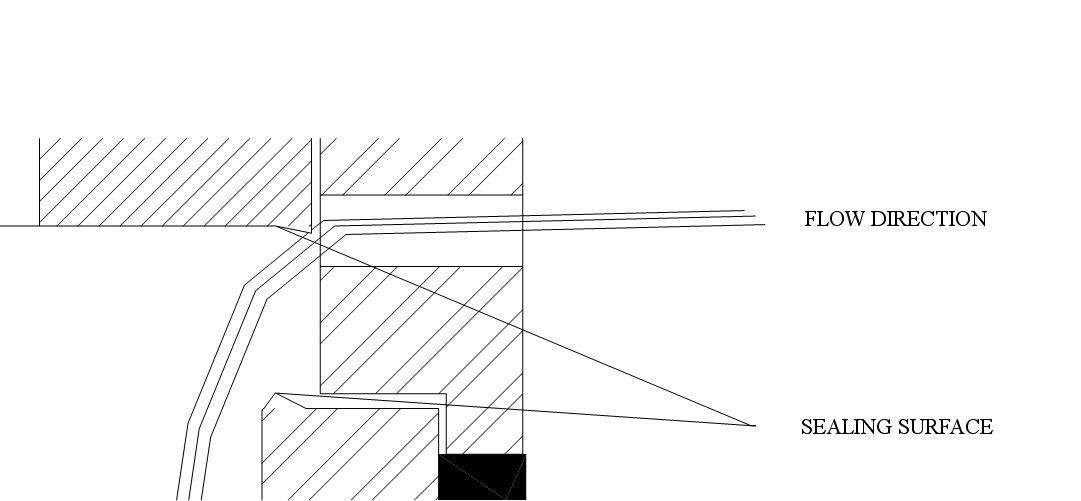

After upgrade, it can be seen that the sealing surface is moved from the original side of the valve core to the underside of the valve core, and the high-speed steam containing water droplets directly impacts on the sealing surface of the valve core without impinging on the side of the valve core, so it can be very good. The protective sealing surface is not damaged by water erosion and thus does not cause leakage.